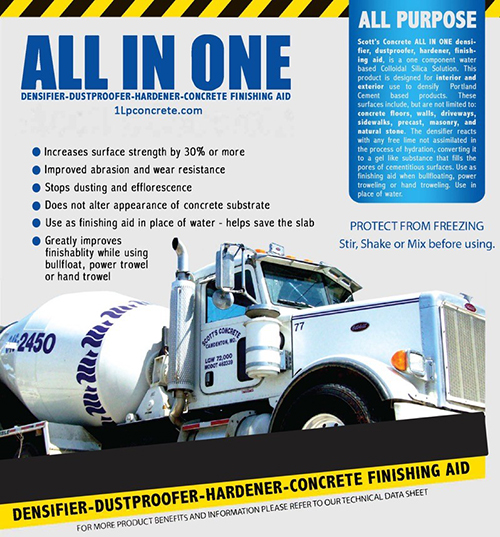

ALL IN ONE

FINISHING AID-HARDNER-DUST PROOFER-PROTECTOR AND 1LP CONCRETE ADMIX

Since 2009 All In One has been at the forefront of the development of Concrete Finishing Aids.

Concrete placement and finishing have always had many challenges that are affected by numerous situations and conditions. With the introduction of 1L cement concrete finishing aids are more important

All IN One Finishing Aid and 1LP Concrete Admix has many advantages.

Ease of Finishing

When All In One is applied or 1LP Concrete Admix is added to the ready-mix the finishing process there will be a noticeable difference in the ease and workability of the concrete surface.

Admix eliminates the use of water on the surface of the slab.

The ability to “close up” and finishable “cream” are immediately noticeable. Using All in One/1LP Admix can make the difference of saving the slab or ripping out and replacing. All In One and 1LP Concrete Admix are the least expensive insurance policies on your job site. Using All In One or 1LP Concrete Admix eliminates the use of water on the surface and damage to the slab. Eliminating loss of surface strength due to cement to water ratio. It will prevent discoloration due to water use during finishing.

Using All In One or 1LP Concrete Admix Greatly Improves the Surface of the Concrete.

When used as a finishing aid or after concrete is placed and cured, there are numerous advantages. By reacting with the Calcium Hydroxide released during the hydration process of the concrete. The surface of the concrete is hardened by as much as 30%. The concrete will also be Dustproofed during this process. The surface is also “densified” during this process. The density of the surface slows evaporation of water during the curing process. This greatly improves the prevention of surface checking and cracking. A denser concrete surface also inhibits the penetration of harmful salts and water which can cause scaling and de-lamination of the concrete surface. Resists staining.

Without 1LP Concrete Admix after One Pass with Laser Screed

With 1LP Concrete Admix after One Pass with Laser Screed

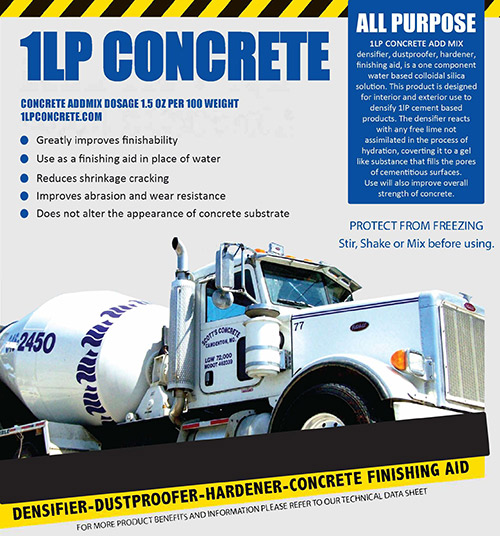

ALL IN ONE

FINISHING AID-HARDNER-DUST PROOFER-PROTECTOR AND 1LP CONCRETE ADMIX

DEVLOPED BY READY MIX PRODUCERS FOR READY MIX PRODUCERS

All In One has been on the leading edge of concrete finishing aids and integral admixture since 2009.

ALL IN ONE & 1LP Admix is specifically developed to be used with ready mix concrete and mortars that use the Portland Lime Cements.

ALL IN ONE & 1LP Admix is available in 5-gallon, 55-gallon drums, 270-gallon totes and 4000 gallon truck load quantities.

Improves Strength

The reactive agents react with the calcium hydroxide released as concrete cures. Up to 20% of the cement used in concrete converts to Calcium Hydroxide. It converts this by product filling the pores of the concrete as it sets. Creating a denser product that slows the release of water. This results in increased concrete strength and surface strength.

Improves Finish-ability of concrete surface

As it reacts, it creates a gel like substance that is cementitious. This cream or gel aids in the finishing of the concrete. Noticeably helps close up the surface and reduces “stickiness” of the concrete. Reducing the need to add water to your surface to aid finishing. Reducing dusting and weakness the concrete surface. Bullfloates and Trowels glide across the concrete surface aiding in the finish-ability of the concrete.

Reduces surface checking

It reduces surface checking by slowing the evaporation of water due to the filling of the pores in the concrete. Less shrinkage due to water loss results in little or no surface checking and increases surface strength.

Reduces or eliminates dusting

It reduces or eliminates the need to use water while finishing the concrete surface. By not increasing the water to cement ratio at the surface dusting is eliminated and it will eliminate the need to use water while finishing.

Does not alter concrete surface

It does not alter the concrete surface in a manner that would be detrimental to the application of overlayments, floor coverings, epoxy or polishing. The surface of the concrete strength and the elimination of dusting vastly improves the adhesion of floor treatments.

Cost Effective

Our product reduces the need to increase cement to increase finish-ability. It also increases strength and durability of the concrete. Customer complaints are greatly reduced saving the need for costly customer QC issues.

Eliminates Efflorescence

By assimilating the free lime in the concrete matrix, it will eliminate efflorescence associated with lime.

Stops ASR

It will actively reduce Alkali Silica Reaction by reacting to many of the siliceous minerals found in some aggregates.

ALL IN ONE

FINISHING AID-HARDNER-DUST PROOFER-PROTECTOR AND 1LP CONCRETE ADMIX

PERFORMANCE FINISH ENHANCING ADMIXTURE

Recent changes in the 1L Cement have created some unique issues when it pertains to the finish-ability of ready-mix concrete.

Since 2009 All In One has been the leader in finishing products involved in placing concrete. We are now offering All IN One Finishing Aid and 1LP Concrete Admix to Concrete Producers in 5-gallon, 55-gallon, 270-gallon totes and 4000-gallon Transport Loads.

All IN One Finishing Aid and 1LP Concrete Admix greatly improves the placement, finish, density, strength and durability of concrete. The chemical make-up of 1LP® was developed by a ready-mix producer for ready-mix producers. Our product has the higher solids contents and higher reactive surface of particles than any other manufacturer we are aware of.

Increased Strength & Economical Use

Uses the calcium hydroxide that is produced during the chemical reaction that occurs during the hydration process as concrete cures. As much of 20% of the cement content in concrete can result in calcium hydroxide. This by product robs the strength of the concrete, causes dusting and generally decreases the quality of the end product.

Reacts with this by product essentially converting it back into cement. This reaction “Densifies” the concrete as it fills pours in the concrete reducing water evaporation during the cure. This process creates a concrete that is far more “Finish-able”. Reducing surface tearing, false surface set, surface checking and de-lamination. The concrete surface is noticeably easier to “Close UP” when bull-floating and finishing. Finishers will find it is unnecessary to add water to the surface to aid in finishing. Dusting is noticeably reduced due to assimilation of the calcium hydroxide. Denser concrete is less likely to absorb water and salts and will have increased and consistent strengths.

Will not inhibit the application of coatings, tiles or adhesives. It enhances the application of topical treatments of a concrete slab.

Does not affect the color of the concrete.